A video demonstrating waterjet cutting technology has been widely shared on social media, claiming that with significant pressure applied to water and forced through a tiny nozzle, it can slice through even the hardest materials, such as rocks, bulletproof glass, iron, and diamonds. Let’s examine the accuracy of the claim made in this post.

Claim: By subjecting water to immense pressure and directing it through a minuscule nozzle, it can effectively cut through the hardest materials, including rocks, metals, bulletproof glass, and even diamonds.

Fact: While pure waterjet cutting can be used to cut softer materials, abrasive waterjet cutting is required to cut through harder substances such as metals and ceramics. This is because abrasive particles like garnet or aluminium oxide are added to the high-pressure water stream, which increases the cutting force and allows for effective cutting of hard materials. Therefore, the claim made in the post that water alone can cut through the hardest materials, including rocks, metals, bulletproof glass, and diamonds, is MISLEADING.

The video in question discusses waterjet cutting technology. Waterjet cutting technology works by using a high-pressure pump to generate a powerful stream of water, which is then forced through a small, specialized nozzle. The waterjet exits the nozzle at high velocity, enabling it to cut through various materials. The cutting process is controlled by a computerized system, which guides the waterjet nozzle along the desired cutting path, ensuring precision and accuracy in the final cut. This computer-guided process allows for intricate designs and complex shapes to be cut with minimal waste and high efficiency.

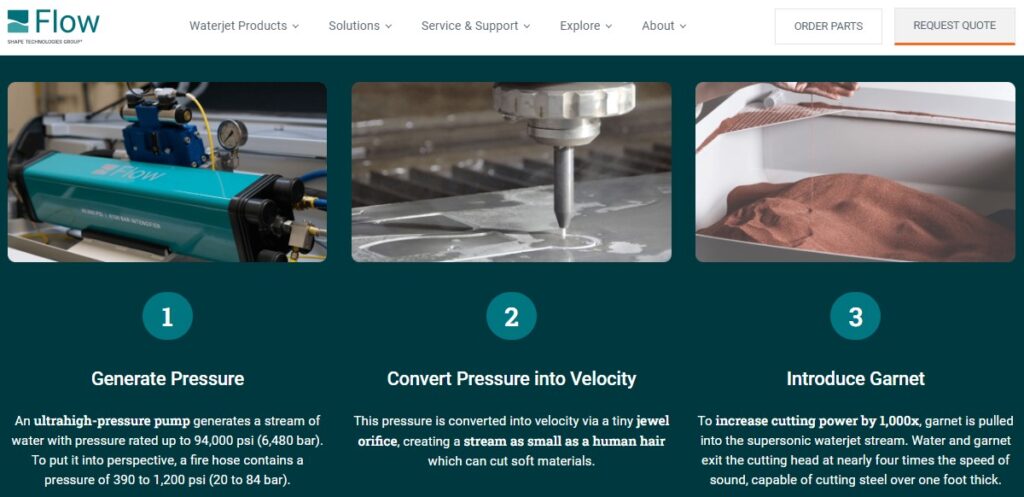

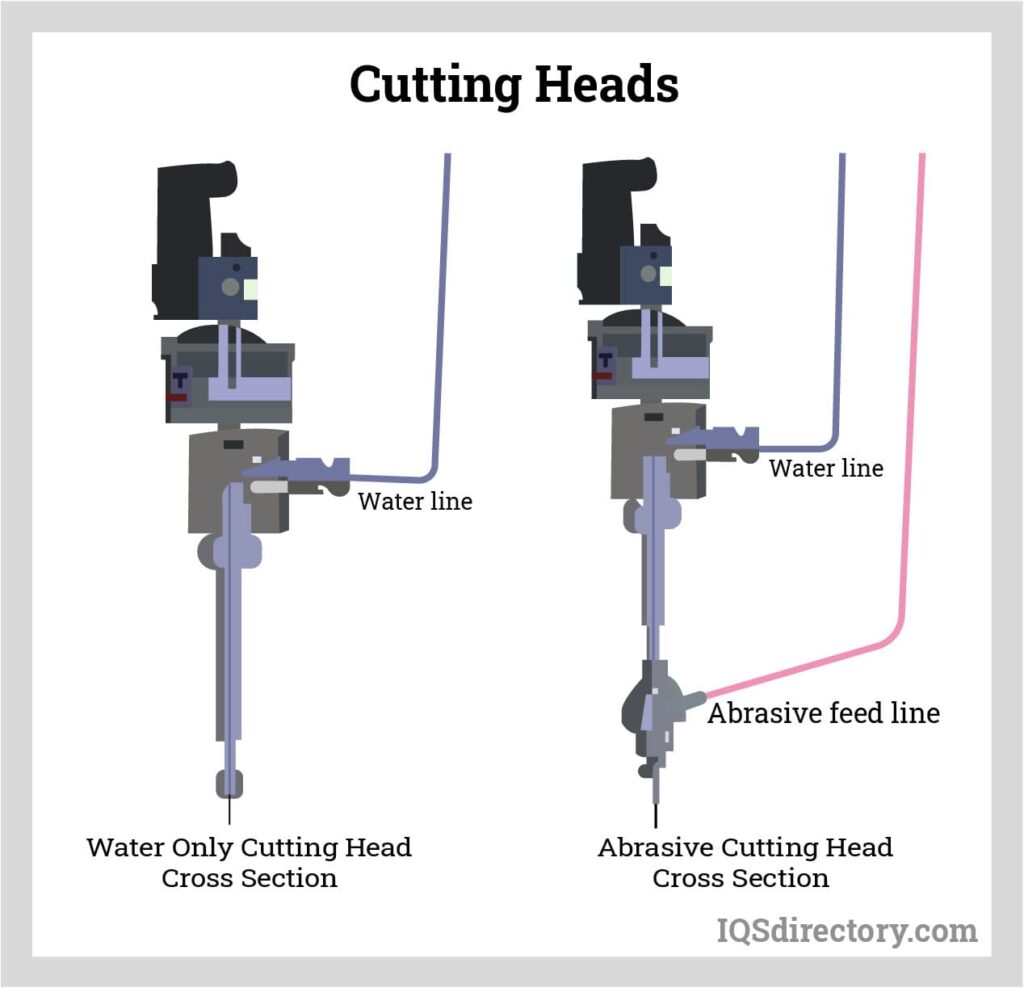

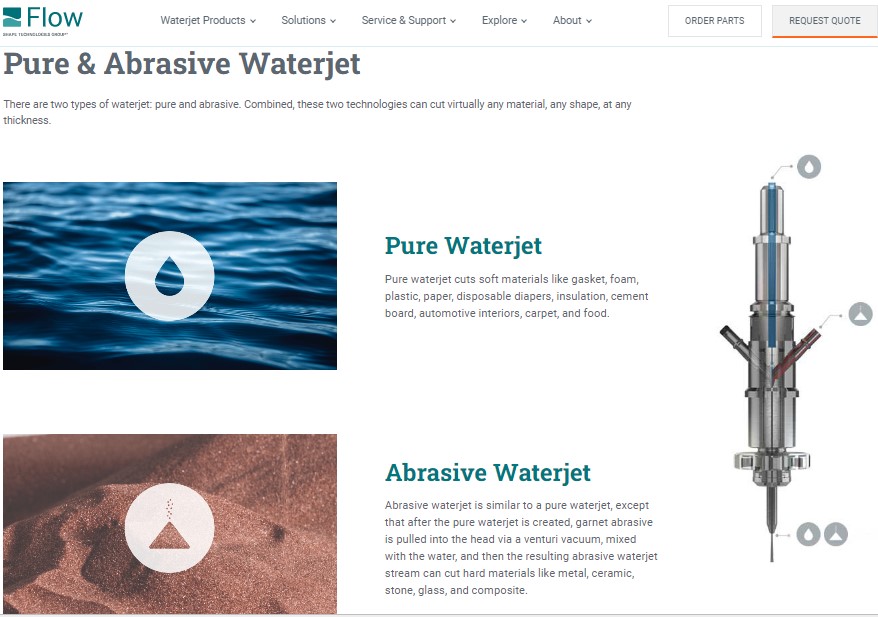

There are two main types of waterjets cutting: Pure waterjet cutting & Abrasive waterjet cutting.

- Pure waterjet cutting: Also known as water-only cutting, this method involves pressurizing water around 60,000 psi (4,100 bar) and forcing it through a small nozzle to create a high-velocity jet of water. The force of the water erodes the material, effectively cutting through it. Pure waterjet cutting is best suited for softer materials, such as rubber, foam, textiles, thin plastics, paper, wood, thin metal foils and certain food products.

2. Abrasive waterjet cutting: In the case of abrasive waterjet cutting, abrasive particles like garnet or aluminium oxide, silicon carbide etc. are mixed into the water stream. The combination of the high-pressure water and abrasive particles enhances the cutting force, enabling the water jet to cut through harder materials like metals, glass, and ceramics.

Abrasive particles in waterjet cutting significantly enhance the cutting capabilities of the high-pressure water stream. They increase the cutting force by getting accelerated within the water jet and impacting the material, causing erosion and material removal. The hardness and sharpness of the abrasive particles allow the waterjet to cut through harder and thicker materials, such as metals, glass, and ceramics, which would otherwise be difficult or impossible with pure waterjet cutting. Additionally, the abrasive particles help create cleaner, smoother edges and enable more precise cutting, making abrasive waterjet cutting an effective and versatile cutting method for a wide range of applications.

Several videos demonstrating the capabilities of abrasive water jets cutting through metals and hard substances can be seen here & here. When it comes to diamond cutting, while some highly advanced abrasive jet machines can cut certain types of diamonds, other efficient techniques are also used, including laser cutting, plasma cutting, and electric discharge machining etc.

To sum it up, while pure water cutting can effectively cut soft materials, abrasive waterjet cutting is necessary to cut through harder substances like metals. Abrasive particles, such as garnet or aluminium oxide, are added to the high-pressure water stream to enhance cutting force and enable the waterjet to effectively cut through hard materials.